Looking back at the history of Modig Machine Tool – over 75 years and three generations of family ownership – it’s clear that the company has certain characteristics that have remained in place throughout its lifetime. A family ethos has, of course, always been at the heart of MODIG, but beyond that there are also qualities that have defined the firm’s actions and goals: innovation, commitment, ambition, and excellence.

The MODIG story

The MODIG story starts in post-war Southern Sweden. In 1947, four brothers, Harry, Sture, Erik and Arne Modig, started a mechanical workshop beside a church in the village of Virserum. The workshop had no heating or running water, and they equipped it with the basics: a used lathe, a second-hand milling machine and a drill. They gave their enterprise a name too: Bröderna Modigs Mekaniska Verkstad – the Modig Brothers’ Mechanical Workshop. After spending a few years repairing furniture and machinery for businesses in the area, the brothers realized that making their own machinery would be a more rewarding business. Their first project would be the bms 1, a fairly straightforward lathe.

Made in 1950, it was notably well-built, sturdy, and reliable. It sold fairly well, but the brothers saw room for improvement. A few years later, the bms 190 was created. It was a clear upgrade on the earlier model, with significantly faster headstock rotation and an easier to maneuver gearbox. From these two early products you can see two of the cornerstones around which modig was built: the brothers aimed to build best-inclass machines, while continually seeking ways to improve and innovate. In effect, they aimed to redefine what ‘best-in-class’ meant in the machining world.

A major breakthrough

A major breakthrough happened in 1962, when they secured an order from the Swedish army for 170 lathes. Not only was this a significant order in its own right, but it also meant future servicing work for the company, transforming them into a firm with an interest in maintaining machine tools as well as building them.

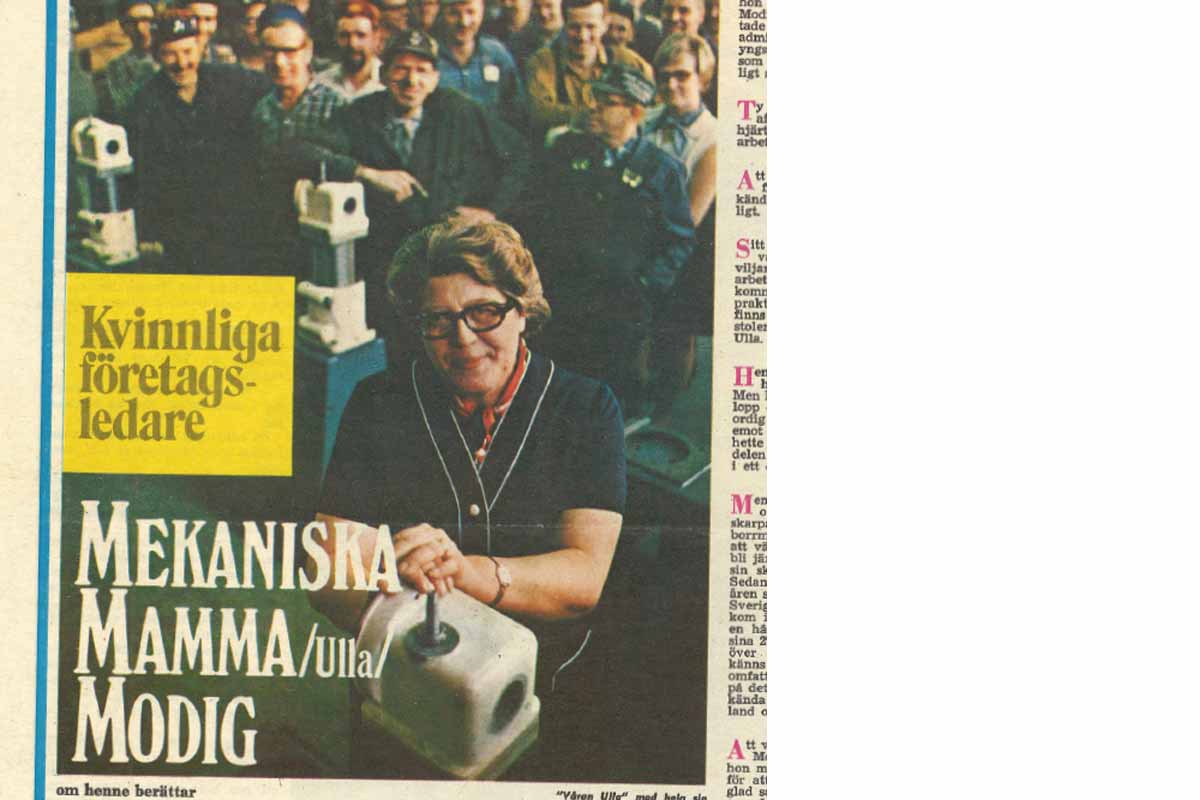

By this time, Harry Modig had become head of the company, but it wouldn’t be accurate to say that he was in sole charge. MODIG remained a family concern, and his wife Ulla was becoming increasingly involved. Ulla Modig took over management of the company when Harry died in 1965. This was an unconventional decision – at that time in Sweden, it was almost unique for an industrial firm to be owned and managed by a woman.

Ulla´s role

Ulla’s role got quite a lot of attention, including one memorable newspaper headline describing her as a ‘Mekaniska Mamma’ –Mechanical Mama! But having Ulla in charge was far from a publicity stunt: she was an astute, ambitious leader. She continually made investments in the firm’s premises and equipment, she secured contracts at home and abroad, and she drove innovations including modig’s universal drilling machines. All the while she took a consensus-based approach to leadership, consulting regularly with employees. It’s an approach that ensured that being a family business meant more than having a Modig in charge. It was about retaining a family ethos too, and valuing the contributions, wisdom, and experience of all its members.

Flow of innovations

Ulla’s son Percy took over running of the company in 1978 – remarkably, he would remain in charge for 33 years. The 80s and 90s saw modig grow and attract larger and larger clients, on the back of a flow of innovations.

Their developments in computerization and high-speed machining brought them international attention. The biggest breakthrough, though, was the Profile Line, a high-speed machining center designed in partnership with the Saab Military Aircraft that could process aluminum profiles of all sizes. It led to significant orders from other aircraft manufacturers, like Boeing, Airbus and McDonnel Douglas, and became the most popular extrusion machine in the aerospace industry. The close links between modig and aerospace continue to this day.

“ 2021 has been as momentous a year as any in MODIG’s history.”

As the company moved towards the 21st century, a third generation of the Modig family became increasingly involved. David, son of Percy, grandson of Harry and Ulla, had been around the company for as long as he could remember – one of his earliest memories was, as a five-year-old, watching in awe as a huge piece of machinery was hoisted into the factory.

He began working on the floor in his early twenties, before progressing through the ranks and eventually taking over from his father in 2011. As well as introducing some of modig’s most uccessful products – like the RigiMill and HHV ranges – David’s tenure has seen the foundation of Modig Machine Tool US Inc. With modig doing so much business in the United States, this decision would help them further establish themselves and increase brand awareness. 2021 has been as momentous a year as any in modig’s history. It’s seen the opening of the North American Headquarters in Wichita, and the expansion of their factory in Kalmar, Sweden (the company’s headquarters moved there from Virserum in 2019.) Perhaps most excitingly, it’s also been the year that modig’s inverted machining centers have been unveiled – hopes are high that it could represent the future of machining as well as the future of modig.

Did this article spark your curiosity? Read more about MODIG in our e-magazine.

E-magazine: Produktion: ROXX Communication Group, Publisher: Modig Machine Tool. Project manager: Micael Lindgren. Text: Brian Cloughley. Photo: Modig Machine Tool/Studio Rosenfors/Lindsberg Media.