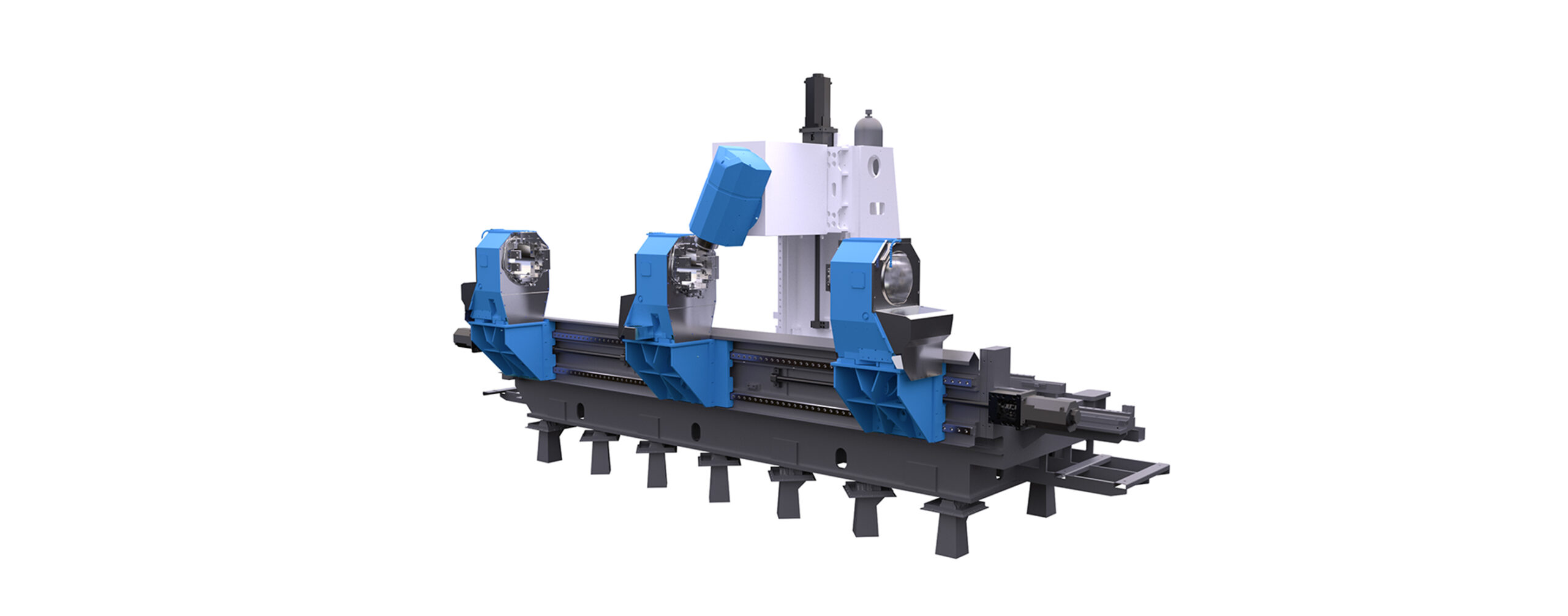

4- or 5-axis. Single spindle. Extrusion- or bar machining. Max part cross section: Extrusion 6 x 10” (150 x 250 mm) Bar 5 x 5” (127 x 127 mm). Vertical machining center with 3 rotary tables.

Highlights: A longer X-stroke travel. MAchining between all rotary tables. B-axis for end work and continuous 5-axis machining. Tool loading during machining.

Industries: Aerospace, Extrusion and more.