3-4-5 axis. Single spindle. Turnkey solutions for vertical machining. Full automation options available. High chip removal rates.

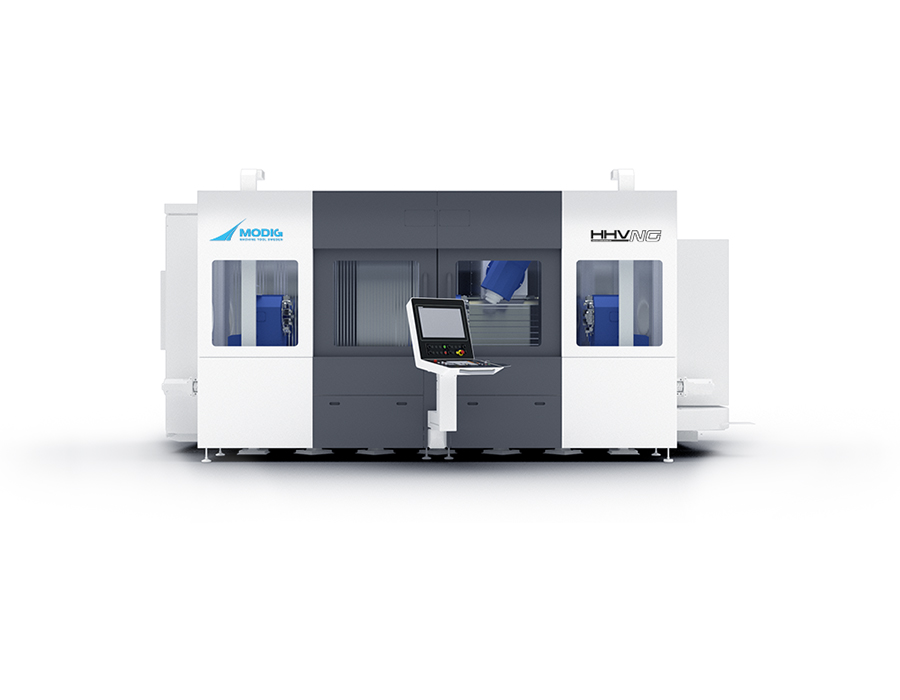

MODIG is recognized worldwide for our innovative adaptations to meet challenging machining requirements while providing unparalleled machining accuracy. This enables our customers to achieve world-class quality – with shortened production times, leading to decreased, overall manufacturing costs. The Vertical Machining Centers, characterized by a spindle being vertically oriented, includes solutions of MODIG’s extensive tradition of innovative machines that continuously enhance the world’s machining standards. MODIG is proud to display the vertical machining center with the world record in highest measured material removal rates (1,200 cubic inches/minute: 19,7 liters/minute) without losing quality or precision. MODIG’s vertical machining centers have several advantages optimized for increased productivity and enhanced machine availability.

What type of industries use MODIG’s Vertical Machining Centers?

MODIG’s vertical machining centers are frequently used in industries such as aerospace and space, for machining of parts in both soft and hard metals with unlimited length.

Article: Gardner Aerospace, one of Europe’s leading suppliers of aerospace detailed parts and sub-assemblies, is implementing MODIG’s next-generation, 24m single spindle, high-speed gantry machine. Read the article!

Success story: MODIG delivered the first RigiMill Moving Table to ASCO Industries. Read the story here!